After a four-year break, the time has finally come again: BAU 2023, the World’s Leading Trade Fair for

Architecture, Materials and Systems, returns and will take place from 17 April to 22 April 2023 in

Munich, Germany. Save the date!

POLFLAM is pleased to announce that we will be exhibiting at BAU 2023 in Munich. We invite you to

visit us at our stand 127 in hall C3.

Discover our state-of-the-art fire-resistant glass solutions including floor applications, smoke barriers

as well as the frameless BR system and curved glass, which is very popular with designers and

architects.

Please contact your local Sales Manager to schedule a meeting.

If you would like more information about fire-resistant glass made by POLFLAM visit our website at

www.polflam.com.

The #BAU2023 is just 12 weeks away!

We look forward to welcoming you to our stand 127, hall C3!

Again and again, the question arises whether curved butt-jointed glass and fire protection are feasible at all? Once again, POLFLAM has demonstrated the performance of curved monolithic POLFLAM BR EI 30 with two opposing curved butt-jointed fire-resistant glasses (convex and concave) in an impressive fire test.

The fire test was successfully performed at DMT in Lathen in a non-load-bearing frameless partition wall system with maximum glass dimensions of 1500 mm x 3000 mm.

This allows the realisation of curved endless partition walls of fire resistance class EI 30 with a variety of different circumferential glass edge coverings.

Curved glass thus offers architects and planners additional freedom in the design of building interiors. In this way unique room structures can be realized without compromising fire safety requirements.

Contact your local Sales Manager to learn more about curved fire-resistant glass made by POLFLAM.

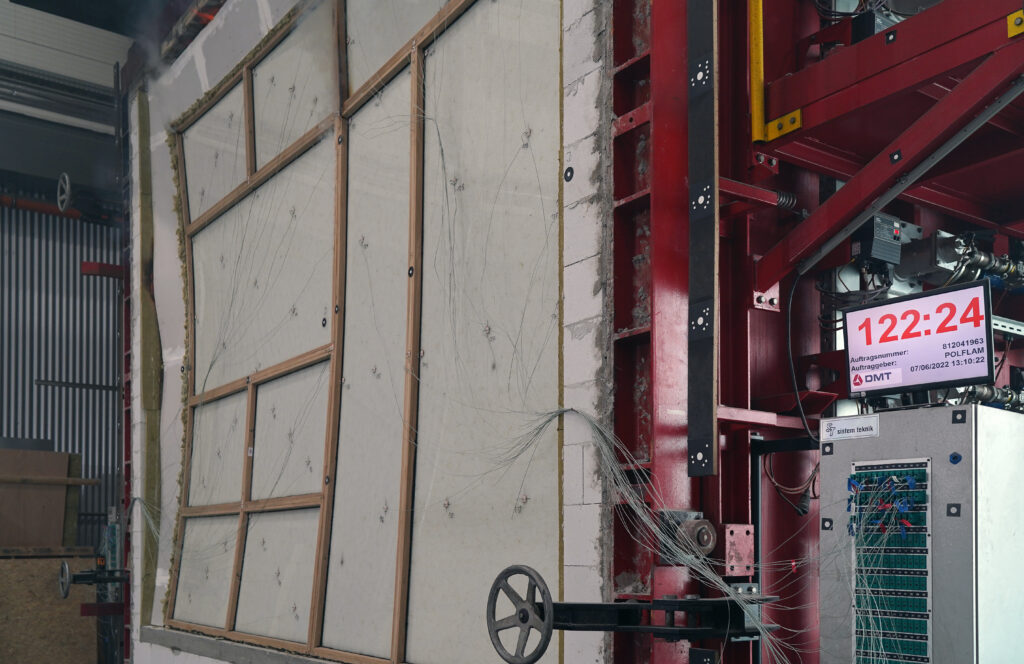

POLFLAM sets new standard for 2-hours fire protection with butt-jointed glazing in an aluminium fire-resistant system.

POLFLAM successfully achieved 2-hours fire resistance (EI120) with POLFLAM BR EI120 (butt-jointed) fire-resistant glass installed in a commercially available aluminium system (Aliplast FR90).

The combination of butt-joint glazing, 2 hours fire protection in an aluminium fire-resistant system with a basic depth of 90 mm is unique for the market, giving designers and architect the possibility to combine endless transparency with 2-hours fire protection in a widely available aluminium fire-resistant system.

With this test result maximum individual glass pane dimensions of 1800 mm x 3000 mm and 1500 mm x 3600 mm (width x height) are possible (EI120) with glass-to-glass (butt-joint) connections creating endless transparent fire-resistant glass partitions.

For more information, please contact your local POLFLAM sales representative.

During the latest test our well-known frameless system POLFLAM BR EI 120 with an impressive glass dimensions of 4.000 mm × 2.500 mm (landscape format) has been fire-tested at the test institute DMT in Lathen. The partition retained its fire resistance performance for more than two hours.

The use of frameless systems ensures maximum transparency and facilitates the creation of appealing interior designs, while maintaining resistance to fire up to EI 120. More often large fire-resistant glass panes are required in landscape format to create an unlimited transparent view in buildings without any framing and with as minimal glass to glass connections as possible.

POLFLAM BR fire-resistant glass is available in extra-large dimensions: 4.000 mm × 2.500 mm (landscape format), 2.400 mm × 4.000 mm and 2.000 mm × 4.800 mm (portrait format).

POLFLAM has successfully completed a series of fire tests on timber partitions for classifications EW 30, EW 60, EI 30, EI 60, EI 90 and EI 120. These are intended for use in rigid and lightweight supporting constructions. The fire tests were carried out in various notified fire test laboratories in Poland and Germany, and the final test of the series (a partition with POLFLAM® EI 120) took place on June 7.

We have completed the move to our new production, warehouse and office centre in Jeziorzany near Tarczyn. Our updated official company address is:

POLFLAM Sp. z o.o., Aleja Krakowska 3, 05-555 Jeziorzany (near Tarczyn), Poland

The new premises is located right next to Expressway S7 be entered via ulica Ogrodowa: https://goo.gl/maps/BZD9d9jBpjoCsycZ7

Our new production facility allows us to increase production capacity and to better serve the needs of our customers across Europe and the Middle East.

After four days of meetings, good conversations and very interesting discussions, the 2022 Nordbygg building and construction fair in Stockholm has come to a close. We had the opportunity to meet our partners and customers again. We were also able to introduce our POLFLAM products to many potential new clients!

The POLFLAM trade fair team (representatives from our headquarters and our Commercial Director Nordics) would like to thank you very much for visiting us and for all the valuable discussions at our booth. We look forward to seeing you again at the next fair!

After two years on a COVID-19 pandemic hold, the exhibition industry is finally returning to normal. On 26 April, Nordbygg, one of the largest construction and building industry fairs in Europe, will re-open its doors in Stockholm. POLFLAM will participate in this exhibition and present a wide range of fire-resistant glass applications, such as glass floor panels and full-size glass elements for frameless systems.

Nordbygg – the go-to fair for the business community in northern Europe – will be open to visitors until Friday, 29 April.

Read more: NORDBYGG

Construction of POLFLAM’s new production and warehouse complex in Tarczyn is being currently finalised.

The production infrastructure, considered to be the most state-of-the-art in Europe, is undergoing testing at the moment. Specialised machinery, equipment and tools for the new plant were supplied by leading manufacturers such as FOREL, Mappi, Bottero and MC DIAM, with the ERP software system provided by FeneTech. The general contractor, CFE Polska, efficiently carried out the construction project following the design-build method.

Along with the combined 15,000 m2 production floor and warehouse , the office area (630 m2) was also opened for use. Outdoor space totalling over 8,000 m2, including access roads, car parks and truck loading areas, has been completed.

The new factory will begin full operational status within the next few weeks. Thanks to the new investment, the production capacity for POLFLAM’s fire-resistant glass will nearly triple.

One significant advantage of POLFLAM’s cutting edge technology over competitors is the ability to create very large fire-resistant glass panes. We are proud to announce that we have developed a new glass product by successfully increasing the maximum height of a single pane of POLFLAM BR glass to 4800 mm.