Increasingly office buildings, and sometimes public utility buildings are constructed based on the assumption that particular storeys will then be divided into rooms at a later stage. Every tenant within their own area can organise rooms or work stations for employees according to his/her own needs.

The easiest way to divide space is so-called light partition walls, where a metal frame is covered with gypsum and cardboard boards from both sides. However, such structures prevent light from reaching places located further away from the building’s external walls and windows. Therefore, glazing is placed in them. If this is necessary, this glazing may be made of fire-resistant window panes.

Office transparency

POLFLAM brand has developed fire-resistant glazing in the BR system, and to assemble them one does not require any frames or posts. Fire-resistant glass panes are mounted directly in walls, which may be made of any material. They are walls such as: masonry partitions, reinforced concrete walls or so-called architectural concrete that looks like a raw wall, currently so attractive for interior designers, and willingly used in industrial interiors. The BR system may be assembled in light partition walls, although for this kind of partitions an entirely different product has been specially designed.

The frameless system is not only aesthetic, but also allows for increasing the area of glazing, and that feature may be really useful.

Developers, owners of commercial buildings, tenants, and last but not least, interior designers can use glazing with the height of 3 metres that extends through the entire height of rooms.

The size of rooms can also be very large, since particular window panes – with a width of up to 1.5 metres – are joined to form a glazing of any length. At joints one must apply a layer of silicone, and the joint may be covered with an elegant, narrow aluminium profile (30 mm in width). Partitions with resistance of El 30 and thickness of 30 mm or resistance of El 60 and thickness of 35 mm can be made of flat or flexible window panes. They are entirely translucent and it is possible to make them in any colour from RAL and NCS palettes. It is worth noting that paints are applied directly on a fire-resistant window pane with no need to use an additional glass sheet.

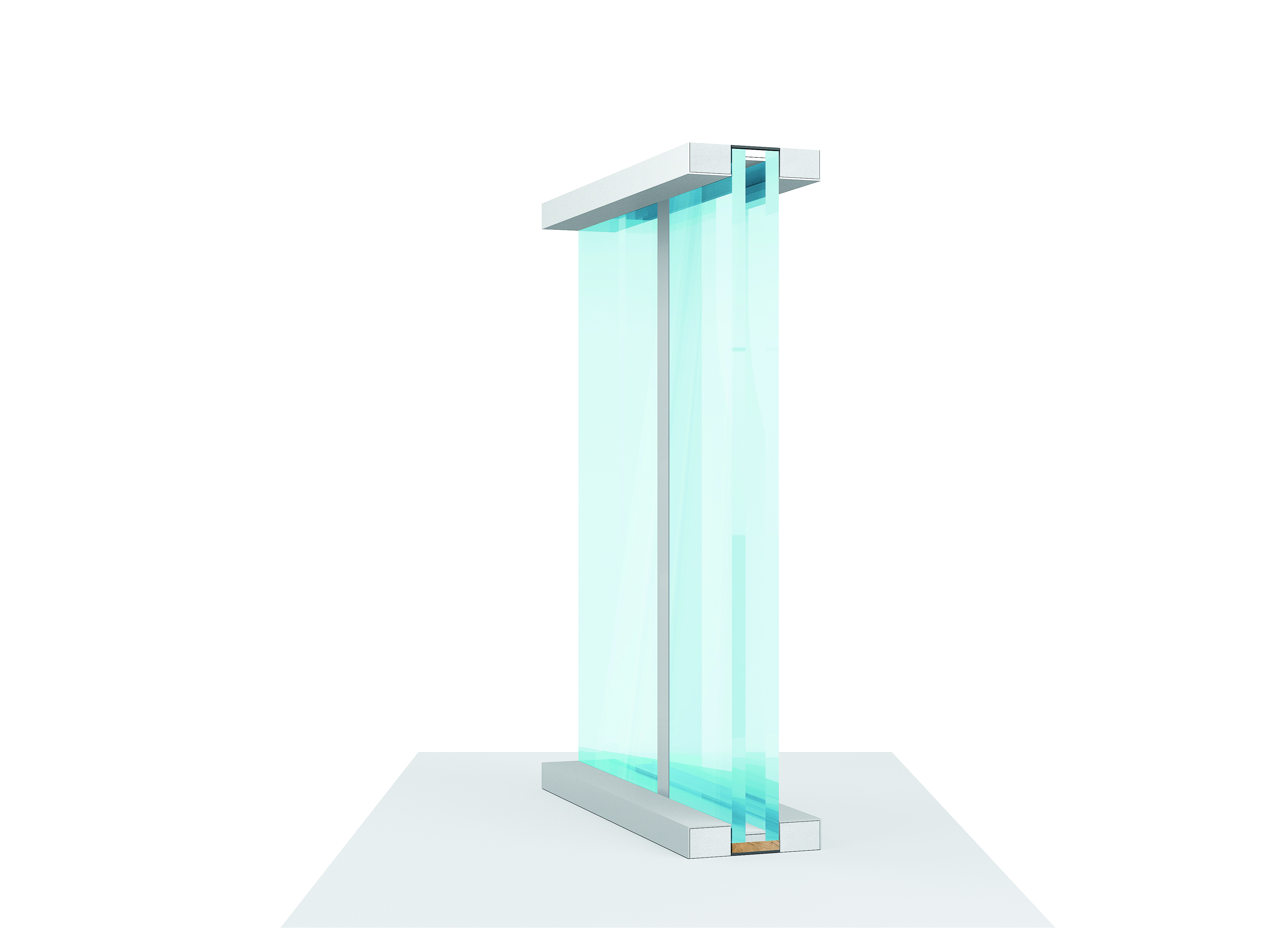

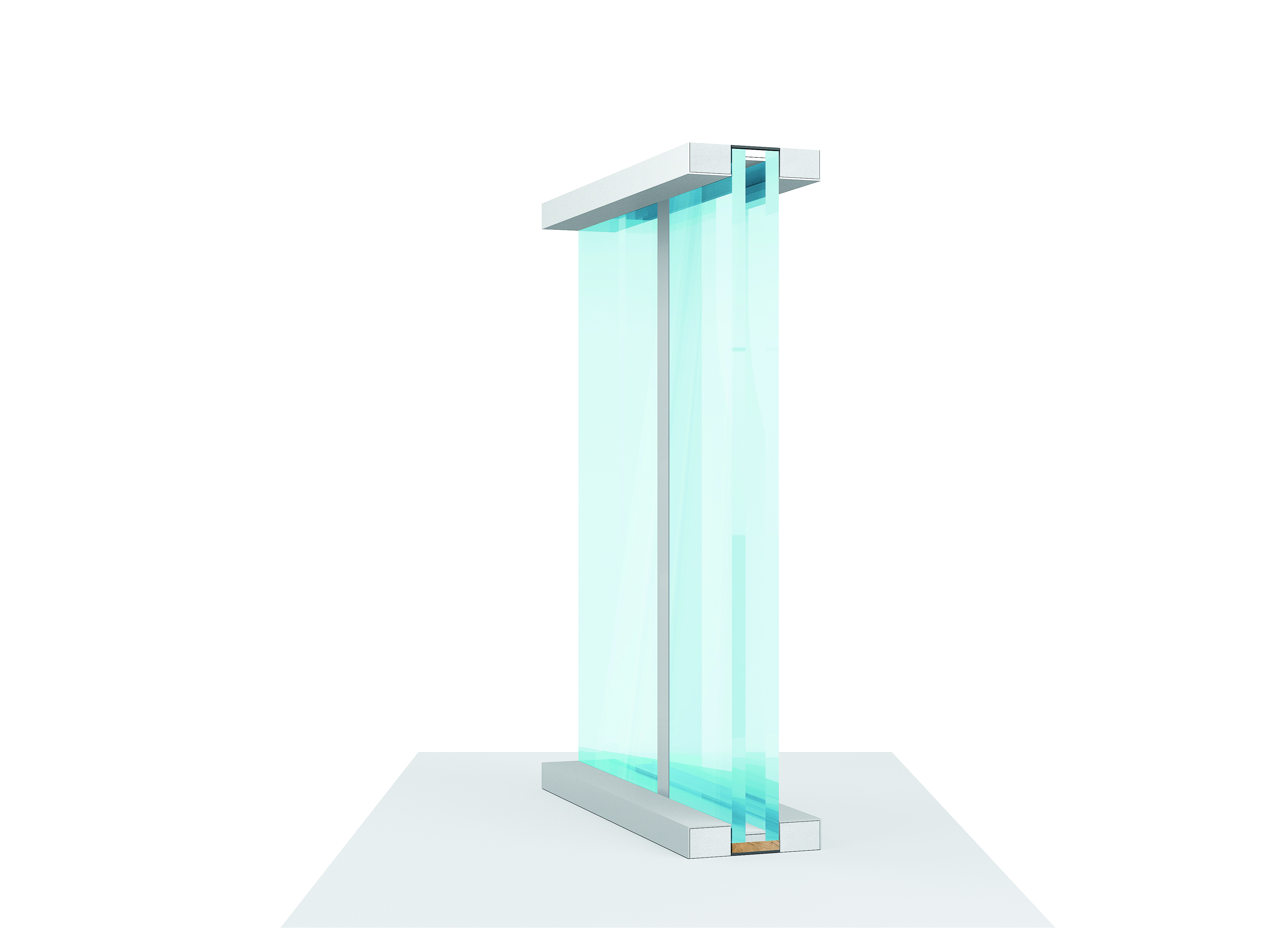

In the BR frameless system the window pane is set without the use of profiles.

BR system from the inside

The BR frameless fire-resistant glazing is firmly set in a wall, owing to appropriate assembly elements. Fire-resistant insulation is ensured by non-combustible cooling blocks placed under the window panes and a tape stuck around the glazing, which is expandable in response to high temperature.

These features are important for fire resistance, although not very beautiful elements, may be covered with gypsum moulds or aluminium angle bars.

The BR system allows for constructing large glazing, which is not limited by frames. It is not unimportant that by applying such solutions one does not need to take into account one more element, i.e. frames, while calculating the resistance of a partition. This system, with simple, almost minimalistic structure, not only allows more light to enter rooms, but it is also aesthetic and cheaper than solutions with frames, and the weight of the entire partition is lower as well.

Fire-resistance in EL30 and El60 classes is suitable enough for most applications. The window pane that resists fire and high temperature for half or an hour allows for evacuating people from endangered buildings.

Therefore, these window panes are used both for, e.g. marking off zones with different functions, as well as separating escape routes, including corridors, halls and staircases from other parts of a building. The BR frameless system can also be used as filling of structure walls of fire separation with proper load bearing capacity. Such solutions, with the use of POLFLAM fire-resistant glass, are offered by FR Solutions (www.frsolutions.pl).

Before long a frameless assembly system of fire-resistant doors in such a wall will be presented.